Designer & Material are made for each other.

If Designers are thorough with Material Science and Mechanics; they can deliver a very productive design to company and finally to end user. Kinematics plays important role during designing process.

To minimize the process wastage, and increase the productivity, one must have clear vision for processes to be adopted for manufacturing and their limitations. Another thing they should consider is safety of Class-C, for product, for user and for environment.

Here are some factors listed (not limited to) to understand balancing material productivity & safety:

- Factor of Safety

- Material Utilisation

- Process Layouts

- Process Sequence

- Feeding to Machine/Equipment/Plant

- Extracting from Machine/Equipment/Plant (Ejection)

- Material Standard – Size / Shape / Properties

- Material Handling

Etc.

Much of arguments done on Factor of Safety. In past days, when material price and availability was not a problem, designers were loving to choose higher factor of safety. Secondly, in those days, one used to come to conclusions through practical applications and field trials only, because simulation and analysis software were not available. But now, designers are equipped with much sophisticated tools for deciding proper factor of safety considering all live threats to product. Material can be saved with proper analysis, selection & factor of safety.

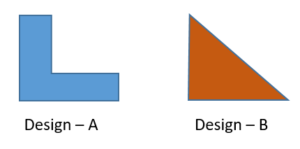

Process Layouts are very important for designers for choosing proper design of the components. For example, if a corner bracket has to be designed for keeping a slotted angle rack in square position, designer may design it like following

Design – A, Process Layout will be

Design – B, Process Layout will be

So, overall productivity of Design – B is greater than Design – A, hence designer may choose it. Another advantage on choosing Design – B is further saving of material because of reduced thickness. Triangle of thinner gauge to give equal amount of robustness will come by L – shaped corner (Design – A).

Many design practices have been adopted by different organisations. Designers must follow those practices and deliver their best. Although, they may suggest scope of improvements to their management.